Pipe Fittings

Air Energy is the largest supplier of bathroom supplies and flexible gas pipe fittings in Australia. We are committed to providing everything you need in one convenient location, including Copper Pipe & Fittings in a number of sizes for all applications and uses.

Our copper pipe selection includes high-quality hard-drawn copper tubes and fittings for use in refrigeration, plumbing, and air conditioning. Air Energy carries the quality brands and manufacturers you know and trust, so you can shop confidently for everything you need in one convenient location.

What Is Pipe Fitting?

Pipe fittings are used to connect pipes. Elbows and tees are piping system components that help to change the flow direction. Reducers and reducing tees change the size of the pipes. Couplings, for example, are used to connect and stop flows, whereas Caps are used to control flows.

Have you found the copper pipe you require? While you’re here, get everything else you need, including a number of different gas copper pipe fittings. Our connectors, caps, and elbows are available in various thicknesses and degrees, as well as copper press fittings and breeches for a wide range of applications.

Find sink assemblies, tap assemblies, and shower assemblies for simple installation, or pick and choose the copper pipe & fittings you require from our fantastic choice.

Different Types of Pipe Fitting Materials

Pipe fittings materials are frequently chosen in connection with piping materials. Cost, flexibility, media, environmental conditions, and required pressure ratings all play a role in selection. Different types of plastic and metal are available as material options.

Common metals include:

Aluminium

Lightweight and resistant to corrosion. Aluminium is a common plumbing material and the preferred fitting material for aluminium piping. Aluminium has a low tensile strength by itself and is used when high corrosion resistance is required. It is alloyed with zinc, copper, silicon, manganese, or other metals to increase its strength and hardness.

Brass

Strong, long-lasting, and corrosion-resistant, with good conductivity and ductility at high temperatures. Brass is a copper and zinc alloy that is commonly used in industry for smaller compression and threaded pipe fittings due to its machinability and excellent performance properties.

Brass fittings can have a variety of protective or decorative finishes that should match the piping finish.

Cast iron

Strong and abrasion-resistant. Because of their resistance to abrasive materials such as sand, gravel, solid wastes, and debris, cast iron fittings and pipes are primarily used in building construction for sanitary, storm drain, waste, and vent piping applications.

Copper

Excellent conductivity and corrosion resistance. Copper fittings are essential in many plumbing and heating applications and are commonly used in residential water supply lines. Copper fittings, which can be soft or rigid, are typically used in conjunction with copper piping.

Soft or ductile copper bends and moves easily, making it the only type suitable for flare connections. Rigid copper cannot be bent and must be routed around corners and obstacles using directional fittings.

Steel

Durable and strong, with high heat resistance. Steel is an iron-carbon alloy that is frequently alloyed with other metals to improve corrosion resistance and durability. It is used to transport water, flammable gases, and other fluids for both commercial and industrial applications.

Galvanised steel is zinc-coated to resist rust and chemical corrosion. Carbon steel is alloyed with more carbon for higher durability and strength.

Stainless Steel

Relatively strong and resistant to chemicals and corrosion. Stainless steel is a steel alloy containing more than 10.5% chromium, providing excellent corrosion resistance for sanitary applications and those dealing with aggressive fluids and materials.

Why Choose Us?

We service a wide range of customers and industries throughout Australia, so whether you’re a licenced tradesman, business, school, university, hospital, facilities management, government, aged care nursing home, manufacturer, hotel & hospitality, cafes & restaurants, or a general consumer looking for quality plumbing products, we have it.

According to Air Energy, all plumbing work should be performed by qualified licensed professionals. You can find what you’re looking for by browsing our extensive product categories or contacting our online service team.

Because of our quick response time and friendly black poly pipe fittings service, we are the obvious choice for online plumbing sales throughout Australia. Air Energy products are covered by a manufacturer’s warranty and meet all industry certifications. This means you can buy the item you require with confidence. If you receive a defective item, Air Energy or the manufacturer will replace it or provide a full refund.

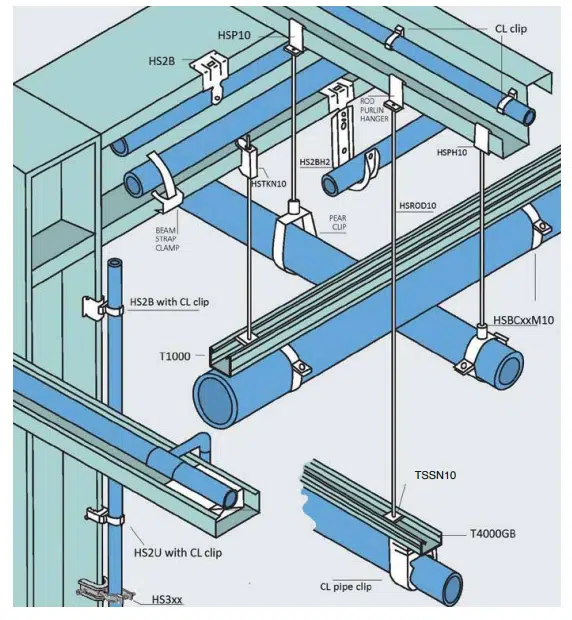

Pipe Brackets

Air Energy stocks a range of pipe brackets, including stand-off brackets, straight brackets, vertical brackets and standard wall brackets. Our fitting accessories also include pipe bracket clamps. All our products are available in different sizes and dimensions. Thus, we have everything for you, whether you need large steel pipe fittings, black poly pipe fittings, or black steel fittings. Our superior quality pipe fittings are available at highly competitive prices across Australia, including Adelaide, Brisbane, Melbourne, Perth, and Sydney.

Pipe Clamps

Hose Clamp Worm Drive

| Code | Size mm | All 316 Stainless steel |

|---|---|---|

| HC8-12 | 8-12 | |

| HC8-16 | 8-16 | |

| HC12-20 | 12-20 | |

| HC16-27 | 16-28 | |

| HC20-32 | 20-33 | |

| HC25-40 | 25-41 | |

| HC30-45 | 30-46 | |

| HC32-50 | 32-51 | |

| HC40-60 | 40-61 | |

| HC50-70 | 50-71 | |

| HC60-80 | 60-81 | |

| HC90-110 | 90-111 |

Hose Clamp for Pipe – Heavy Duty Bolted

Hose Clamp 2 Ear Crimp

Accessories

| Product | Code | Size | Description |

|---|---|---|---|

| Ceiling Penetration Flange |

CPF14 | up to 14mm | protects edges of holes in plaster ceilings or ceiling tiles restrict entry of insects etc. |

| CPF19 | up to 19mm | ||

| CPF25 | up to 25mm | ||

| CPF32 | up to 32mm | ||

| CPF38 | up to 38mm | ||

| CPF48 | up to 48mm | ||

| Floor mount post | FMP | 75mm x 75mm x 2 metre | Utility services pole mount for power, data point, compressed air outlet hose reel, etc. Jack chain attachment |

| Outlet mounting bracket | TFWM15 | ½" hole | Wall bracket to rigidly mount Tf or EF compression outlets suits 20, 25, & 32 pipe fittings |

| TFWM20 | ¾" hole | ||

| Threaded cover plate | SSWCP15 | ½" hole | Stainless steel mounting flange with BSP female outlet |

| SSWCP20 | ¾" hole | ||

| SS wall cover plates 2" x ¾" |

SSSCP15 | 15mm | Split half Escutcheon plates pre or post-fitting wall cover plate |

| SSSCP22 | 22mm | ||

| SSSCP28 | 28mm | ||

| SSSCP35 | 35mm | ||

| SSSCP42 | 42mm | ||

| SSSCP54 | 54mm | ||

| Wall Penetration Flange | WPF15 | ½" bsp | PN16 rated ½"BSP female outlet suits wall thickness up to 85mm plus backing nut. |

| Weatherproof pipe penetration seal | DEK05-55 | 05-56mm | EPDM flexible weathertight seal suitable for pre or post installation. Ozone & UV resistant. Full range of sizes. -40℃ to 115℃ |

| DEK25-70 | 25-71mm | ||

| DEK50-100 | 50-101mm | ||

| DEK90-150 | 90-151mm | ||

| DEK125-200 | 125-201mm | ||

| Retrofit clip | DEKCLIP | Aluminium or SS clasp to seal retrofitted flashing joint |

|

| Mounting pad | AVR-S | 65 x65 x9 | Anti vibration rubber pad - honeycomb pattern |

Pipe Clips

Air Energy offers cutting-edge pipe clips that are both innovative and versatile. Our products are designed to meet the diverse needs of pipe mounting applications, providing a simple, quick, and reliable solution. With a range of unique features, our pipe clips offer a distinct advantage over traditional mounting options. We prioritise customer satisfaction by delivering high-quality solutions that streamline installation and ensure long-lasting performance.

Experience the convenience and durability of our plastic pipe clips, copper pipe clips etc., for your pipe mounting projects.

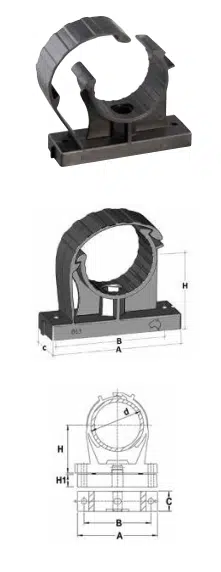

Product Specifications:

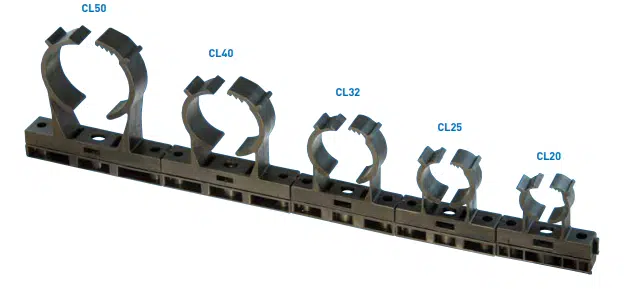

Our pipe clips are crafted using premium-grade polypropylene, sourced exclusively from virgin materials. It ensures exceptional durability and eliminates the risk of brittleness or breakages. We offer a range of sizes to cater to various pipe diameters. Choose from CL20 (18-22mm), CL25 (25-28mm), CL32 (31-35mm), CL40 (39-44mm), and CL50 (47-53mm). Our latest addition, the CL63, is the result of extensive research and development, showcasing a robust and rugged design. Experience the unmatched quality and reliability of our pipe clips, engineered to exceed your expectations.

Innovative design features include:-

- Very heavy duty will replace need for bolted clip heads.

- One-piece construction- no loose nuts, bolts saddles etc.

- Choice of centre or side fixing.

- Centre recess holds 10mm nut for all thread applications.

- Compatible for nylon anchors.

- Open access for drills or cordless tools.

- Secure positive double latch design.

- Anti-friction grooves facilitate longitudinal pipe expansion.

- Virgin PP material – almost unbreakable

- Dovetail interlock compatibility

- Reinforced base and mounting holes

- Accidental disconnection protector

- Suits vertical wall or overhead installation

- Mounts perfectly on Unistrut style channel.

- Non-corroding suits PE, PP, SS, Aluminium pipe systems

- Environmentally friendly, 100% recyclable

| Code | size d | A | B | C | H | H1 | H1 |

|---|---|---|---|---|---|---|---|

| CL 20 | 18 - 22 | 56 | 41.5 | 14 | 28 | 10 | 10 |

| CL 25 | 25 - 28 | 62 | 47 | 16 | 30 | 10 | 13.6 |

| CL 32 | 31 - 35 | 67 | 52 | 16 | 35 | 10 | 15.8 |

| CL 40 | 39 - 44 | 86 | 70 | 18 | 40 | 10 | 21 |

| CL 50 | 48 - 53 | 94 | 78 | 18 | 46 | 10 | 24.6 |

| CL 63 | 63 | 123 | 103 | 40 | 70 | n/a | 77.4 |

| TYPICAL PROPERTIES | Method | Value Unit |

|---|---|---|

| Physical | ||

| Density (Method D) | ISO 1183 | 0.90 g/cm³ |

| Melt flow rate (MFR)(230℃/2.16 kg) | ISO 1133 | |

| Mechanical | ||

| Tensile stress at yield | ISO 527-1, -2 | 23 Mpa |

| Flexural modulus | ISO 178 | 1050 Mpa |

| Impact | ||

| Notched izod impact strength | ISO 180 | |

| 23℃, type 1, notch A | 6.0 kJ/m² | |

| 0℃, type 1, notch A | 3.5 kJ/m² | |

| -20℃ , type 1, notch A | 3.0 kJ/m² | |

| Hardness | ||

| Shore hardness (Shore D) | ISO 868 | 66 |

| Thermal | ||

| Heat deflection temperature B (0.45 Mpa) unannealed | ISO 75B-1, -2 | 70℃ |

| Heat deflection temperature A (1.80 Mpa) unannealed | ISO 75A-1, -2 | 50℃ |

| Vicat softening temperature (Method A) | ISO 306 | 150℃ |

Pipe Support Spacing

| Code | Up to 25 C | Up to 50 C |

|---|---|---|

| AIR20 | 700 | 600 |

| AIR25 | 900 | 750 |

| AIR32 | 1200 | 900 |

| AIR40 | 1400 | 1100 |

| AIR50 | 1600 | 1200 |

| AIR63 | 1800 | 1400 |

| AIR90 | 2000 | 1600 |

| AIR110 | 2400 | 1800 |

| AIR160 | 2700 | 2100 |

Before beginning, if installing pipework along a wall, mark a straight line with a laser or chalk line. Old text manuals stipulated to allow fall on all horizontal pipes in the direction of flow, to allow for drainage of condensate. The best practice is to include a dryer and filters after the receiver to remove damaging condensate. Nevertheless, low points that could become water trap hazards should be avoided if the dryer is turned off or not working. It is recommended to allow drainage discharge points at significant locations, especially for any underground installation.

- Mount clips at approved spacing, allowing for expansion and extra support on either side of branch lines, droppers or isolating valves.

- Vertically mounting clips for a horizontal pipeline, ensure the female ratchet is uppermost.

- Spread apart the 2 arms of the clip and insert the pipe.

- Press the pipe down into the clip so the 2 arms self-lock around the pipe. Adjust the tightness of the ratchet grip.

- To remove the pipe from a clip, push the 2 arms in opposite directions longitudinally to disengage the ratchet.

Clip spacing may need to be adjusted for various ambient temperatures that may be encountered. Refer to the technical department. For vertical pipework, clip spacing can be increased by approx. 20%. Spacing will need to be decreased if the pipework is conveying liquids.

Pipe Flanges

Flanges play a vital role in connecting valves to the pipework. It provides convenient access for removal and maintenance purposes. A wide range of pipe flange standards exists, and flanges within the same standard can be categorised:

- Flat face (typically made from cast iron or ductile iron)

- Raised face (usually crafted from cast steel or stainless steel).

Other facings include:

- Ring Joint (RTJ)

- Male and Female (Spigot and Recess)

- Tongue and Groove

- O-Ring Groove (O-Ring Spigot and O-Ring Groove)

Our expert will assist you in choosing critical flange dimensions and identifying the specific standard you’re working with. This valuable information will aid in accurately determining the flange standard applicable to your project. Count on our comprehensive expertise and high-quality flange solutions to meet your requirements.

TABLE E: Screw Flanges NP 16 bar AS 2129 1994

| Part No | NOMINAL FLANGE SIZE | INCH SIZE | P (mm) | D (mm) | T (mm) | G (mm) | BOLT HOLES No. x dia | BOLT |

|---|---|---|---|---|---|---|---|---|

| CFEF.000015 | 15 | 1/2” | 65.0 | 95 | 14.0 | 2.0 | 4 x 14 | M12 |

| CFEF.000020 | 20 | 3/4” | 75.0 | 105 | 16.0 | 2.0 | 4 x 14 | M12 |

| CFEF.000025 | 25 | 1” | 85.0 | 115 | 16.0 | 2.0 | 4 x 14 | M12 |

| CFEF.000035 | 32 | 1¼” | 100.0 | 140 | 18.0 | 2.0 | 4 x 18 | M16 |

| CFEF.000040 | 40 | 1½” | 110.0 | 150 | 18.0 | 3.0 | 4 x 18 | M16 |

| CFEF.000050 | 50 | 2” | 125.0 | 165 | 20.0 | 3.0 | 4 x 18 | M16 |

| CFEF.000065 | 65 | 2½” | 145.0 | 185 | 20.0 | 3.0 | 8 x 18 | M16 |

| CFEF.000080 | 80 | 3” | 160.0 | 200 | 20.0 | 3.0 | 8 x 18 | M16 |

| CFEF.000100 | 100 | 4” | 180.0 | 220 | 22.0 | 3.0 | 8 x 18 | M16 |

| CFEF.000125 | 125 | 5” | 210.0 | 250 | 22.0 | 3.0 | 8 x 18 | M16 |

| CFEF.000150 | 150 | 6” | 240.0 | 285 | 24.0 | 3.0 | 8 x 22 | M 20 |

Pipe Fasteners

CLIP HEAD TO SUIT HS3

| Part # | Description | Pipe size mm |

|---|---|---|

| HS320 | clip head to suit HS3 BOLTED PIPE CLIP | 20 |

| HS325 | clip head to suit HS3 BOLTED PIPE CLIP | 25 |

| HS332 | clip head to suit HS3 BOLTED PIPE CLIP | 32 |

| HS340 | clip head to suit HS3 BOLTED PIPE CLIP | 40 |

| HS350 | clip head to suit HS3 BOLTED PIPE CLIP | 50 |

| HS363 | clip head to suit HS3 BOLTED PIPE CLIP | 63 |

Hanging System Components

Can I use a flexible pipe for the gas line?

How do you connect flexible gas pipes to fittings?

Use the proper fittings and connections to make gas line connections from steel or copper pipes to ranges and clothes dryers safe and secure. To connect flexible gas pipes to fittings, follow these three simple steps:

Step 1: Connect to the steel gas pipe.

Step 2: Soft Copper Connections

Step 3: Reusing a Soft Copper Coil