Air Quick Connect Couplings

Safety, energy efficiency and dependability are at the centre of Air Energy’s quick connect couplings. Air Energy recommend only reliable brands and styles; there are other imitations or copies on the global market, but pressure drops caused by poor internal design can be a very costly but hidden running cost.

ACCIDENTS IN THE WORKPLACE can be costly. Injured employees suffer, and companies can experience financial setbacks. The power of compressed air has the potential to cause serious or even fatal injuries. One dangerous situation occurs when operators use their fingers or hands to block the air stream, such as when dead-ending a blowgun. The incoming air can damage human tissue severely, and even a small amount of injected air can adversely affect blood supply.

Also, when disconnecting a long length of hose under pressure, the blast resulting from the sudden expansion of air has the potential to startle operators; whiplash can cause physical injury as well as hearing damage.

- A blast of air under 40 p.s.i. from 4 inches away can rupture an eardrum or cause brain damage.

- As little as 12 p.s.i. can pop an eyeball from its socket.

- Air can enter the navel, even through a layer of clothing, and inflate and rupture the intestines.

- Directed at the mouth, compressed air can rupture the lungs.

Since compressed air has the potential to cause serious operator injury, its handling is safeguarded by industry standards and usage guidelines. Employers are responsible for ensuring the safety of employees by providing instructions on the proper use of compressed air, as well as providing equipment and tools that are safe to use. Standards regarding the use of compressed air differ from country to country. We strongly believe in the importance of caution when using compressed air. Below are some applicable standards around the world.

- Australia’s “Duty of Care” requires that employers do everything reasonably practicable to protect the health and safety of others in the workplace.

As such, it is your responsibility to ensure that you have taken all relevant steps to ensure the safety of all personnel within your area of responsibility. Manufacturers in Australia can fulfil this responsibility by specifying pneumatic products that comply with such internationally known standards as:

- European Standard EN 983:1996 – Safety of Machinery Paragraph 5.3.4.2.7.

- International Standard ISO 4414 – Pneumatic Fluid Power Paragraph 9.6

Both standards specify the same functional requirements for quick-action (release) couplings in pneumatic fluid power systems.

International Standard ISO 4414 – Pneumatic fluid power Paragraph 4.2. This standard specifies hazards that need to be eliminated by system design or by means of a system design that incorporates safeguards against such hazards.

Don’t wait for accidents to happen!

Invest in safety products now.

Safety solutions saves lives and money.

Despite their ease of disconnection, our quick connect fittings offer strength and performance that are superior to those of others on the market.

Premium Quick Connect Fittings

- Push-to-connect feature

- High maximum allowable pressure

- Manufactured to AS/NZ standards

- Multiple applications (e.g. air compressors and water systems)

- Anti-hose whip options

- Ensures secure connection

- Corrosion resistant options

- Suitable for potable water distribution

- Ergonomic, comfortable to handle

Frequency of Use

The frequency of use has a bearing on coupling selection. For heavy-duty use, the selection of materials that maximise wear resistance should be considered.

Safety

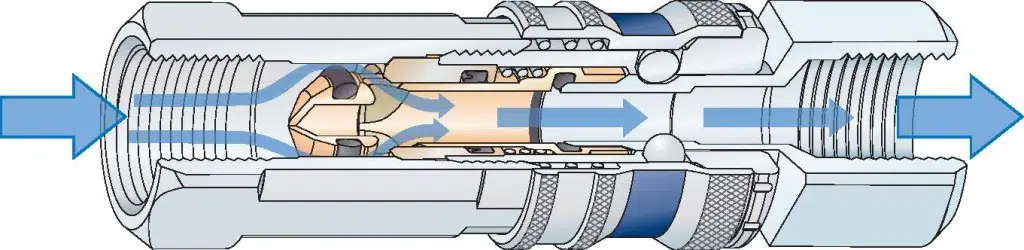

Safety, of course, is a major consideration and this will depend on your plant’s design and the air volume in the pipes or hose. Consider a coupling equipped with a ball check valve or a zero-pressure coupling to prevent hose whipping.

Air Energy Endorsed Products

Air Energy believes in “energy saving through intelligent design”. That is why we specialise in offering products that ensure energy efficiency, resulting in savings for our clients.

Our range of quick connect air hose couplings has been selected for their durability and high performance, preventing costly compressed air leaks and ensuring optimal efficiency.

Best Practice Solutions

Air Energy has been supplying industrial pipework systems for more than 20 years. We have built our reputation and a solid client base through our professionalism, expertise and bespoke ‘best practice’ solutions.

Need Help Selecting Couplings?

Let us know your requirements, and we will help you get reliable, leak-free, easy-to-use, energy-efficient and safe Quick Connect couplers.

Poorly selected couplings create problems with energy conservation, productivity and safety. Deciding on quick connect fittings for compressed air depends on service requirements. Below, we give an overview of selection factors.

Air Energy can help you select the best quick connect air fittings and more. Call us today.

Industrial Applications Of Quick Coupling

Fittings called quick connect couplers are made to make connections and disconnections of hoses and equipment safely and quickly. Hence, there is no need to use shut off valves, or bleed the system.

The main focus of these couplers is convenience with minimal pressure drop in the connected status. Quick connect couplings for fluids can decrease or completely stop fluid spillage in both downstream and upstream directions which prevents product loss.

The design of the quick connect coupling can have huge but not visible economic costs or savings in functionality. The annual cost of electricity consumed to compensate for the pressure drop of inefficient couplers can be several times more than the cost of purchasing a quality coupler that lasts for years.

What are safety couplers?

Many OH & S-aware companies are adopting mandatory safety couplers in all their operations.

Safety couplers are designed to safely release downstream pressure before total disconnection can be completed. This protects the operators from the dangers of potential hose whips and the noise of sudden discharge. This noise can exceed 120 decibels. equivalent to a jet plane taking off and lead to permanent industrial deafness. The other obvious danger is unrestrained pressurized air can cause particles to penetrate the eyes.

Some Other Types Of Couplers

Various types of couplers are used in the industries depending on the usage and type of equipment used. Each type of coupling has its advantages, disadvantages, and specifications.

There are many different and specific couplers available, which it would be confusing to list here., such as breathing air and diving. Lockable couplers designed for connecting polyurethane hoses without hose clamps.

One special coupler that is loved by all who try it is the impact resistant plastic coupler. It is very lightweight and greatly reduces the risk of damage to products, whether it be furniture or vehicles.

Rubber protection sleeves are another option available, as are dust caps, to maintain the cleanliness of the couplers when disconnected.

Advantages of Press Tools Air Energy

Pressing is far less complicated than soldering, brazing, or welding. The installer slides a press-style fitting over the pipe, attaches the appropriate press jaw or press sling over the fitting, and pulls the trigger. The press tools Perth cycle creates a strong, leak-proof connection in less than 5 seconds.

The following are the most significant advantages of press tools in Adelaide:

Time

This is the most obvious — and surprising — a benefit to contractors who try pressing for the first time after years of using traditional methods.

Pressing is quick. Many different fitting types can be pressed in under 10 seconds, saving significantly more time than other methods. On average, press technology saves between 50% and 90% of the time. Multiplying the time saved per fitting by hundreds or thousands on a large job can trim days off a project.

There is also no time for rest for curing and drying.

When making repairs, the speed of pressing is a huge benefit. Pressing saves time because it can be done on wet pipe systems, eliminating the need to shut down the system and dependent operations during the fix and allowing the contractor to work and make connections more quickly. It can save customers hundreds of thousands of dollars in lost downtime in commercial and industrial applications.

Money

Every firm understands that time is money. The time savings provided by pressing allow contractors to bid more competitively, cut labour costs, and take on more jobs — benefits that can make a significant difference in the bottom line.

Compressing is approximately 30% less expensive when comparing installation costs to welding and threading. Regarding labour costs alone, pressing is 80 percent to 90 percent less expensive than welding, 30 percent to 50 percent less costly than threading, and up to 60 percent less expensive than jamming.

Safety

Because pressing is flameless, it is safer than traditional systems and does not require flux, flammable gases, or fumes. As a result, the system is simpler and safer to install than traditional pipe-joining methods. Because there is no flame, there is no need for a fire watch, which saves money.

The pressing tools eliminate the need for costly and heavy equipment such as welding tanks and threading machines, which can be challenging to transport and time-consuming. Users are also not required to wear welding helmets or other safety equipment.

Press tools Brisbane is also more environmentally friendly because it does not require welding rods or cutting oils. Besides that, because a good job is clean, pressing leaves no joining material buildup, exposed threads, or tarnish, resulting in a clean, professional appearance.

Reliability

Nothing is more frustrating than being called back to a job because of a leak that went undetected during the work or developed later due to poor pipe joining. It is costly and embarrassing and can also ruin your reputation with the client and lead to a negative word-of-mouth experience.

Traditional techniques leave more room for user error and inconsistency and are less reliable than pressing.

Why Choose Us?

Air Energy was created to facilitate the quick and easy assembly of industrial pipework systems using press fitting. This method creates a dependable, secure, and long-lasting seal, ensuring a high-quality system on which you can rely.

Press fitting, as opposed to welding, provides a safe alternative while also shortening installation time. Air Energy is also ideal for constructing pipe systems in tight spaces where traditional welding would be too dangerous.

Reliable filtration at its best! Our air compressor filters deliver exceptional performance, protecting your equipment and delivering clean air for optimal efficiency.

Don’t hesitate to get in touch with our experts if you require any additional information. We can check to see if your press tools Sydney will work with our system or advise you on what tools you will need for your project.