Vastair

Fast, Flexible, Easy to modify Aluminium Piping System 16.5 mm to 168 mm

Vastair Durability & Flexibility:

| Fluids | High Resistance to | Certification and Guarantee |

|---|---|---|

| Compressed air (dry, wet, lubricated) | CorrosionThermal Variations | Certification ISO 9001 version 2000 |

| Vacuum | Aggressive Environments | TOV Certification QUALICOAT |

| Inert gases {argon, nitrogen) | UV | Certification ASME 831.1 |

| Other fluids: please consult us | Mechanical Shocks | |

| Compressor Oil Carry Over |

Maximum working pressure

- 13 bar from -20°c to +60°C

- 16 bar from -20°C to +45°C {except for 168mm)

Vacuum level

- 98.7 % {13 mbar absolute pressure)

Working temperature

- from -20°C to +60°C

Storage temperature

- from -40°C to +80°C

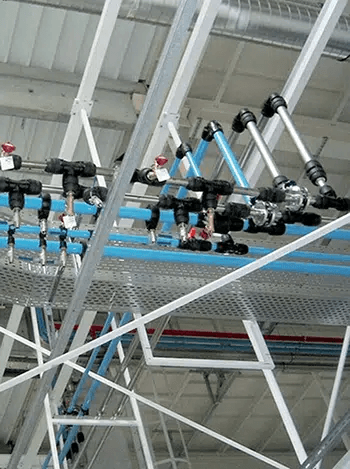

Vastair system benefits

There are many advantages to be gained from using Vastair aluminium pipework systems

- Completely adaptable – dismountable and reusable components.

- Energy saving

- Clean air: consistent high quality internal surface.

- High flow rate performance: full flow connection and low friction internal surface of the pipe.

- Optimum sealing: Calibrated pipe diameter.

- Easier handling

- No preparation required: Pipes and fittings are supplied ready for immediate installation.

- Time saving: Quick assembly – no need to weld, glue or crimp.

- No in-depth training required: easy to assemble.

- Easier working on site: Lightweight, easy to cut pipe material.

- System quickly ready for test and use: Immediate start-up.

- Safety – non-flammable materials

- COMPONENTS GUARANTEED FOR 10 YEARS

The Vastair Advantage

Significant savings on installation, maintenance and operating costs

This brand’s compressed air pipe systems are quick to install and ready for immediate pressurisation. Components are removable, interchangeable and allow for immediate and easy layout modifications.

Optimal machine and tool efficiency

The “full bore” design of Vastair components, the low friction coefficient of aluminium pipe and the sealing characteristics of the system ensure optimal and constant flow throughout.

The answer for complete projects from the compressor to the workstation

These systems are designed for both primary and secondary distribution systems used for compressed air, vacuum and inert gases, from the smallest workshop to the largest factory.

Clean air quality protects equipment

Vastair aluminium pipe ensures a total absence of corrosion. The inner pipe surface consistently delivers clean compressed air.

Vastair Technology

Innovative technology at the heart of this product enables rapid and easy assembly: quick connection of components to the aluminium pipe. This technology takes into account the specific requirements of each diameter and provides the user with an optimum safety coefficient and easy connection.

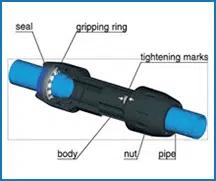

Ø16.5, Ø25, Ø40

Pipe-to-pipe and stud connectors in Ø 16,5, Ø 25 and Ø 40 can be immediately connected to pipe – simply push the pipe into the connector up to the connection mark. The gripping ring of each fitting is then automatically secured and the connection is safe.

Ø63

Pipe-to-pipe and stud connectors in Ø 63 can be quickly connected to aluminium pipe by means of a double clamp ring. This secures the connection between the nut and the pipe – tightening of the nuts secures the final assembly.

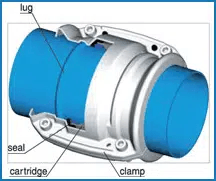

Ø76, Ø100, Ø168

Pipe-to-pipe and stud connectors in Ø 76, Ø 100 and Ø 168 can be quickly connected to aluminium pipe. Position the pipes to be connected within the cartridge and close / tighten the clamp.

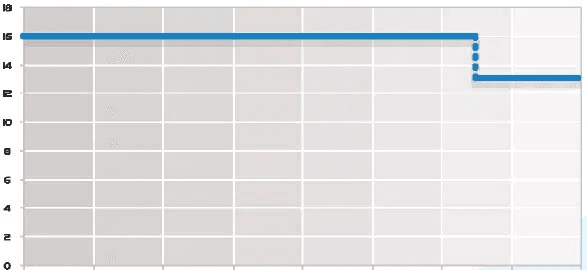

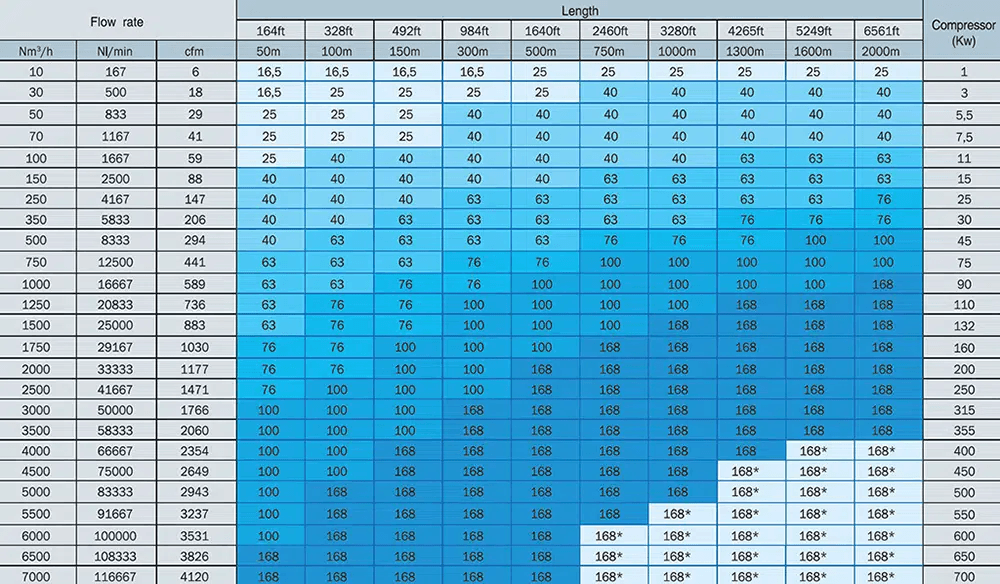

Sizing

Select the diameter for your application based on required flow against pressure drop. Estimated values for: a closed loop network, a pressure of 8 bar with 5 % pressure drop. Velocity is not taken into account.

Example

- Main network length (ring main):300 meters

- Required flow rate: 250 Nm3/h (147 cfm)

- Compressor power: 20kW

- Working pressure: 8 bar

The most suitable diameter is Ø 40

Air Energy can come to your worksite and complete a full and comprehensive audit of your compressed air piping system. To see if your needs might be better served with Vastair, give us a call today on (03) 9765 5600.